Gas Resistojet Thruster for Medium Size Satellite Attitude Control

Badania nad satelitarnym silnikiem korekcyjnym typu resistojet wyposażonym w dedykowany układ zasilania oparty na technologii superkondensatorów.

Introduction

Importance of small and medium satellites has become increasing in last several years. While the range of their application is growing, the appropriate propulsion system must be developed as well. In many missions, volume and mass of the propulsion system make up more than half of the satellite or space probe. Reduction of mass and volume of the propulsion system demands using devices of high specific impulse and high density of storable propellants. The best specific impulse is obtained by the ion engines but the thrust is very small. High density of the propellants is offered by chemical propulsion. However the satellite chemical thrusters typically use hydrazine and nitrous tetraoxide which are extremely toxic substances. Therefore, if a mission needs the thrust in range of 0.1÷1 N and high specific impulse at level of 200 s electro-thermal propulsion can be considered as an effective and cheap solution. It is especially attractive in design and development of the small satellites which are very often built by small organizations with limited resources. The electro-thermal propulsion is much safer and easy to handle but important problem here is high demand for electric power, especially when pulses of large total impulse are necessary. In order to overcome this problem a new kind of resistojet is proposed. The resistojet is powered not directly from the satellite power system but from its own power delivery system based on supercapacitors.

Resistojet construction – based on capillary tubes

After many ideas and research on heating element which is the most important in case of resistojet thruster the idea of using a capillary tubes has been chosen as the most prommisiog one. First analysis were conducted for the stainless steel tubes with inner diameter of 1 mm and outer diameter of 1.6 mm. Electrical resistance of 1 m long tube allows on direct heating by electric current. It was found that it is possible to build a power system with use of commercially available supercapacitor and electronic switches (solid state) which enable use of high current for the direct heating of the metal. The peak voltage can be at level of 60 V and peak current 75 A.

The general idea of the resistojet with capillary tubes is very simple. The tube is connected through electronic switch to a battery of supercapacitors. When the switch is on the electric current heat up the tube and the propellant flowing through the tube to a nozzle. After the pulse, the current flow is switched off and supercapacitors are recharged by spacecraft power system.

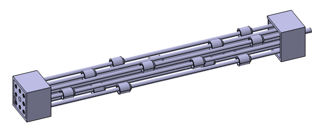

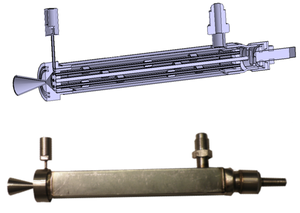

Several models of resistojet with a heater based on capillary tubes have been build. The last version of a thruster with a major modification of a construction have been done after simulation how the size of area around the pipe influence on the results. It allowed to establish the optimal distance between the pipes and the chamber walls. For more optimal distribution of a tubes inside the heating chamber, the shape of whole thruster was changed into tetrahedron one. Additionally, cases were made of 0.3 mm stainless steel sheets and laser welded what allow to limit the mass of a thruster comparing to previous versions. After few more minor modifications, the final version of a thruster consists of tetrahedron shape heater with 8 pipes 115 mm long organized in such way, that it was connected serially in electrical point of view and in parallel in flow point of view. Ceramic element was introduced onto every pipe to protect them from contact with each other, and short circuit. Central pipe was replaced by the solid element because of very hard work condition and possibility of damage. Final version of a heater is shown in figure 1 and a whole heater is presented in figure 2.

Figure 1. Final version of a heater based on capillary tubes.

Figure 2. Final version of the resistojet thruster.

To lower the heat loses flowing gas has beed heated in three stages. After introducing the as into inlet it flown between an internal and external cases. Then in the secon stage it flows around and along the tubes on their outer side. Finally in third stage it flown through the pipes and is deliver into the nozzle where expands and producing the thrust.

Power Supply System

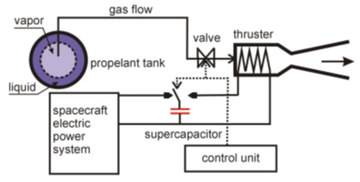

One of the most important issue of operating in a pulse mode is very fast heating of a working gas. Power supply need to be able to deliver very high power into the gas, in a short period. On the other hand, it shouldn’t have significant impact on spacecraft power system and other inboard apparatus. The device which meets those requirements is supercapacitor. It is possible to achieve very high power for short periods of time while the superacapacitor is discharged and the average power consumed for charging supercapacitor in range of tens of watts, which is the acceptable value even for small satellites. Supercapacitor stores energy and, due to small internal resistance, is able to release it in very short time with high current. The concept of resistojet thruster with power supply based on supercapacitors is shown below.

Figure 3. The concept of resistojet powered by supercapacitors.

During the normal flight system remains on standby mode. If any maneuvers are required, supercapacitors are charged by spacecraft electric power system. To power the thruster only by the supercapacitors, they are disconnected from charging system before start the thruster and work independently. During the working of the thruster system is discharged by resistance of the resistojet circuit. After switching off, supercapacitors are reconnected to charging system and recharge if necessary. Completely empty supercapacitor should be charged within 10 minutes, but during one pulse, not whole aggregated energy is used so practically this time will be shorter.

Results of simulation prepared in PSIM software have shown that for 80V of supercapacitors bank voltage and time of 1 s, power released on 1 Ω resistojet heater is about 4.6 kW. Energy transferred into heater in every pulse equals about 4.3 kJ. Discharging impulses are separated by time of 20 s. This time is sufficient for recharge supercapacitors between pulses.

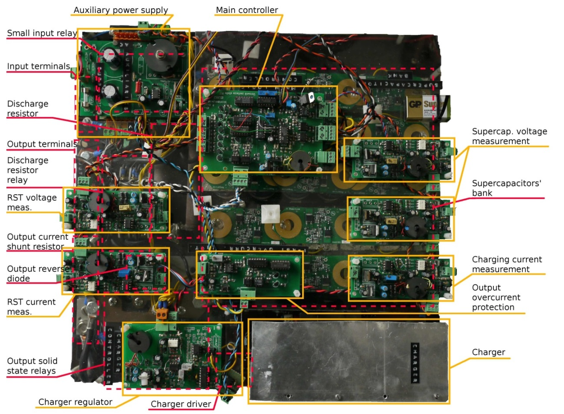

Physical device is based on LSUC supercapacitors. Each of them has capacitance of 350 F and can deliver 2.8 V of voltage. Whole bank consists of 30 supercapacitors in serial connection which gives an maximum output voltage of 84 V an capacitance of 11,67 F.

Figure 4. Supercapacitors used in power delivery system.

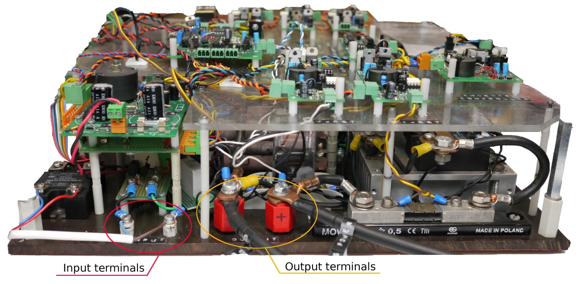

The device can be fully controlled by external signals e.g. from control computer. It’s equipped with series of protection mechanisms (overcurrent, overvoltage) and measurement devices. Thanks to visual indicators, proper work of a device can be checked and eventual problems can be found in a short time.

Figure 5. View of the resistojet power supply system: dashed lines - bottom, power layer; continuous lines - upper, control layer.

Figure 6. Power supply - view of output and input terminals.

Resistojet performance

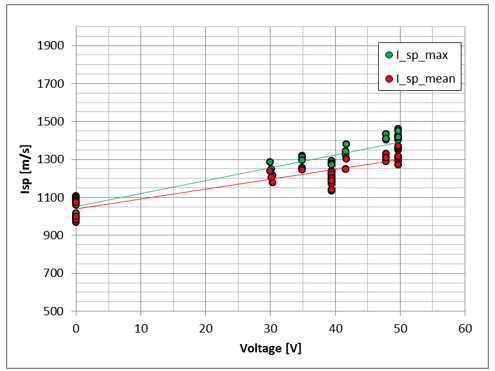

Ammonia has been used as a main ropellant because of its thermodynamical properties. System has been also tested for propane and butane. It allows to change propellant easly. During the research the following specific impulse have been obtained according to initial voltage of supercapacitors bank:

Figure 7. Specific impulse versus initial voltage of supercapacitors bank for ammonia as a propellant.

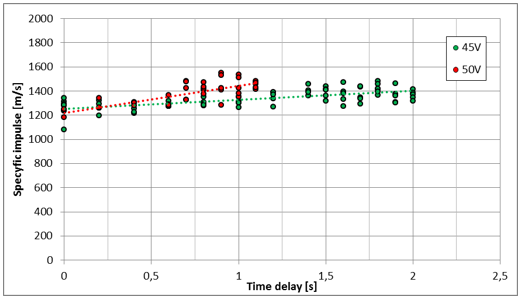

For further improvement of performance of resistojet, time shift between gas and power start have been introduced. Thank to that gas have been delivered into preheated heater what improves the dynamic of a system and let to achieve higher performances. Simulation of time shift influence on specific impulse is shown below:

Figure 8. Influence of time shift on specific impulse.

Summary

The main goal of the work was development of a new type of resistojet equipped with its own electrical energy storage system based on supercapacitors. The work ends on laboratory model phase. New solution allows obtaining high peak of power when the mean power consumption remains low. Delivering the power into the working gas improves the specific impulse which is one of the most important features indicating the quality of propulsion system. Three types of propellant gases have been examined – ammonia as a main, propane and butane as additional ones.

First stage of the work was developing the light, low thermal inertia heater. Many concepts have been examined – bulb glowers, oscillating elements, porous elements but final version of a thruster was based on stainless steel capillary tubes. Nine 120 mm length tube have been organized in square shape and connected serially using stainless steel connectors. It assured the electrical resistance on level allowing on direct connection to voltage source with reasonable current level. From gas flow point of view tubes are connected in parallel so they are not causing significant pressure loss. In addition heater based on stainless steel tubes is mechanically and chemically resistant what allow to use it in final version feeded by ammonia.

Even with decision of using capillary tubes, few version of a thruster have been developed before the final version was established. All versions have the same idea of using the triple way of gas flow to lower loses to the ambient. Major difference is the shape of a thruster cases – roller or rectangle shapes. After the Fluent simulation it was decided to use a rectangle one because of easiest way o even distribution of pipes with the most optimum distances between them and between pipes and internal case. Less important although still required changes can be spotted in gas inlet system, back cap sealing and anti-short-circuit system.

Power delivery system is crucial for resistojet thruster applications. Higher power delivered into the gas let to achieve better performance and lower the mass flow rate. That led to lowering the mass and volume of working gas and its tank, thanks to lowering the fuel consumption. One of the most important demands, next to possibility of delivering a required power level, is mass and volume of power supply. Promising solution for such purpose is supercapacitors thanks to their high power density. It means that the device with relatively low mass is able to deliver high level of power. Single supercapacitor chose for the project has weight of 65 gm, capacitance of 350 F and can deliver 2.8 V of voltage. The power supply for resistojet thruster is based on 30 serially connected devices what gives a voltage on level of 80 V and capacitance of 11.7 F. It has been developed and tested with resistojet thruster and it seems to be promising solution for such applications.

Mathematical model of system consist of capillary tubes resistojet powered by supercapacitors has been developed. ResistojetSC software for simulation of such system has been developed based on mathematical model. This tool has been used for optimization of working point for a thruster and compared with experimental results. Some differences between results obtained from calculations and experiments showed that the model must be used with a dose of caution. Choosing a proper parameters and constants is very important for obtaining results consistent with reality.

The project have been successfully finished with the end of June 2013. As a result a laboratory model of resistojet thruster with higher performances (specific impulse) comparing to cold gas system has been built (900 m/s- cold gas, 1400 m/s resistojet). In simple way it can be transform to lowering the required mass of propellant. Assuming the mass of 30 supercapacitors on level of 2 kg and additional electronic equipment of 5 kg it is still promising result to use in small and medium satellites and prolong or expand the mission tasks.